Bipolar membrane electrodialysis (BMED) is an advanced and sustainable electrochemical separation process widely used for various industrial applications, especially in sectors that require efficient acid and base production and wastewater treatment. This article delves into the intricacies of BMED, explaining its principles, benefits, applications, and the innovative ways it has transformed processes across multiple industries what is bipolar membrane electrodialysis forkid .

Understanding Bipolar Membrane Electrodialysis (BMED)

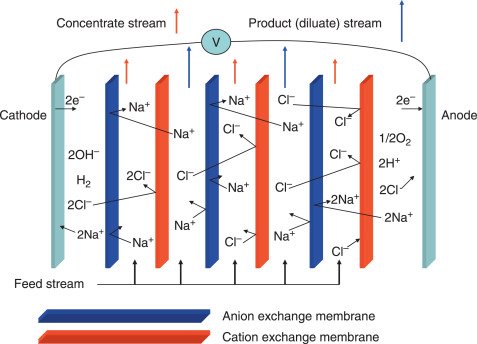

Bipolar membrane electrodialysis (BMED) is a membrane-based process that operates through electrodialysis but incorporates bipolar membranes. In BMED systems, bipolar membranes are integrated with conventional cation and anion exchange membranes within an electric field. This setup drives the separation of salts into acid and base solutions while keeping contaminants minimal, making it ideal for industrial applications that require pure chemical outputs and effective waste management.

Principles of Bipolar Membrane Electrodialysis

BMED operates based on electrodialysis but uses bipolar membranes, which are designed to split water molecules into hydrogen (H⁺) and hydroxide (OH⁻) ions. Here’s a step-by-step look at the primary components and function of a BMED system:

- Bipolar Membranes: These specialized membranes consist of two layers (anionic and cationic), promoting the dissociation of water molecules under an electric field. This layer separation enables the production of acids and bases without added chemicals.

- Cation and Anion Exchange Membranes: These membranes allow selective passage of ions. Cation membranes permit the flow of positively charged ions, while anion membranes allow negatively charged ions to pass.

- Electric Field Application: When an electric field is applied across the BMED system, ions migrate according to their charges. The bipolar membrane in the system splits water, releasing H⁺ ions toward the acid compartment and OH⁻ ions toward the base compartment.

Mechanism of Action in BMED

- Ion Movement: As ions migrate, cations move toward the cathode while anions move toward the anode. When ions reach the bipolar membrane, water splits into H⁺ and OH⁻.

- Acid and Base Formation: The generated H⁺ ions combine with anions in the acid compartment, forming an acid, while OH⁻ ions combine with cations in the base compartment, forming a base.

- Selective Separation: This separation process is highly selective, enabling efficient acid and base production with reduced contamination.

Advantages of Bipolar Membrane Electrodialysis

BMED has several key benefits that make it superior to traditional methods of acid and base production. Here are some of the most prominent advantages:

- Chemical-Free Process: BMED splits water molecules rather than adding external acids or bases, minimizing the use of harsh chemicals.

- Cost-Effectiveness: By generating acids and bases in situ, BMED reduces chemical purchase and disposal costs.

- Environmental Sustainability: The process supports zero-liquid discharge initiatives, aiding wastewater management without contributing to chemical pollution.

- Enhanced Selectivity: With the use of specific ion exchange membranes, BMED allows for targeted ion separation, delivering high-purity outputs.

- Energy Efficiency: BMED uses lower energy than traditional acid/base generation, reducing operational costs for industries.

Applications of Bipolar Membrane Electrodialysis

1. Industrial Wastewater Treatment

BMED is increasingly popular in wastewater treatment for removing heavy metals and other contaminants. Through selective ion separation, it enables the reuse of water while recovering valuable salts. BMED helps industries meet environmental regulations and reduce their ecological impact.

2. Food and Beverage Industry

In the food and beverage industry, BMED plays a significant role in producing organic acids, such as citric acid and lactic acid. The process minimizes chemical residue, ensuring product purity, and is often used to adjust pH levels without adding synthetic chemicals.

3. Pharmaceutical and Chemical Manufacturing

BMED’s ability to produce high-purity acids and bases is invaluable in pharmaceutical and chemical production. The method ensures low contamination, making it ideal for processes that require stringent quality control. BMED is used to generate compounds like sodium hydroxide and hydrochloric acid, essential in various drug and chemical formulations.

4. Renewable Energy and Battery Recycling

In the renewable energy sector, especially in battery recycling what is bipolar membrane electrodialysis forkid , BMED is employed to reclaim valuable components from battery waste. By breaking down complex salts and recovering base and acid materials, BMED supports sustainable energy practices and reduces resource wastage.

How Bipolar Membrane Electrodialysis Differs from Traditional Electrodialysis

Bipolar membrane electrodialysis differs from traditional electrodialysis in the way it handles water splitting and ion separation. While traditional electrodialysis only moves ions across cation and anion membranes, BMED actively produces acids and bases due to its unique bipolar membrane structure. This difference allows BMED to deliver distinct advantages in acid/base production without chemical additives.

Comparing Efficiency and Environmental Impact

- Traditional Electrodialysis: Primarily used for desalination, focusing on the removal of ions without creating acids or bases.

- Bipolar Membrane Electrodialysis: Targets acid and base production, making it ideal for closed-loop processes with minimized waste.

BMED’s environmental benefits stem from its ability to operate without added chemicals, making it cleaner and more eco-friendly than other separation methods.

Challenges in Bipolar Membrane Electrodialysis

Though highly effective, BMED has certain challenges, mainly in terms of membrane stability, fouling resistance, and initial investment costs.

- Membrane Durability: Bipolar membranes can degrade over time, especially in high-intensity processes. Researchers are continually exploring ways to enhance their longevity.

- Fouling: Like other membrane processes, BMED faces fouling, where particles clog the membranes. Regular cleaning and maintenance are required to keep the system functional.

- Capital Investment: The initial cost of BMED setups can be higher compared to traditional methods, though long-term savings often justify the investment.

Innovations and Future Directions in Bipolar Membrane Electrodialysis

Continuous advancements are enhancing BMED’s efficiency and durability, making it increasingly viable for broader applications. Innovations include:

- Enhanced Membrane Materials: Development of more robust and fouling-resistant membranes can extend system lifespan and reduce maintenance needs.

- Energy Recovery Systems: Integrated energy recovery components in BMED systems could help reduce energy consumption, making BMED even more cost-effective.

- Automation and Monitoring: Advanced monitoring systems are improving the precision of BMED processes, enabling industries to control ion separation with greater accuracy.

Conclusion

Bipolar membrane electrodialysis (BMED) is a transformative technology that addresses key needs in acid and base production, wastewater treatment, and various what is bipolar membrane electrodialysis forkid manufacturing industries. Its efficient, chemical-free approach to ion separation makes it an eco-friendly and cost-effective choice for companies aiming to achieve sustainability and meet regulatory requirements. As BMED technology continues to evolve, it’s set to play an even more prominent role in driving sustainable industrial processes worldwide.